Does electric weed control work on herbicide resistant weeds?

At a glance

- Herbicide resistant weeds are becoming more of a challenge for growers, with many species of cropping weeds showing resistance to at least one herbicide mode of action.

- The Department of Primary Industries and Regional Development (DPIRD) is leading an Australian-first project that investigates electric weed control in association with AGXTEND, a brand of the company CNH Industrial.

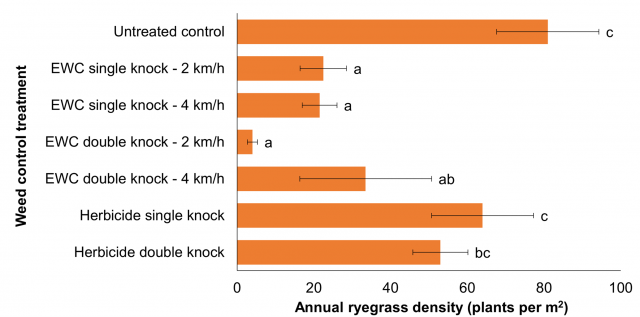

- In an experiment conducted in 2023, electric weed control reduced the density of glyphosate-resistant ryegrass by more than half compared to herbicide treatments.

- Electric weed control is showing potential as a non-chemical alternative for managing problem areas of herbicide resistance.

Herbicide resistant weeds are becoming an increasing issue for growers across cropping areas of Australia. More than 35 crop weed species have developed resistance to at least one herbicide mode of action. Annual ryegrass (Lolium rigidum) is one of the costliest weeds to manage in annual winter cropping systems in Southern Australia, and many populations are developing resistance to both selective and non-selective herbicides.

Finding alternative approaches to manage herbicide resistant weeds, like annual ryegrass, presents a significant challenge. Early trials of electric weed control, also known as electroweeding, are demonstrating its potential as a viable method for controlling resistant weeds.

In an Australian first, the Department of Primary Industries and Regional Development (DPIRD), in association with AGXTEND (a brand of CNH Industrial), is leading a project to trial electric weed control as a non-chemical weed control option. This project, now in its second year, is co-funded by the Grains Research and Development Corporation (GRDC), Wine Australia, and the Cotton Research and Development Corporation (CRDC), with additional in-kind support provided by AHA viticulture and the West Australian Local Government Association (WALGA). The project aims to assist primary industries and community land managers in developing sustainable, non-chemical approaches for weed control.

The XPower electric weed control machine, powered by Zasso™ technology, employs mechanical energy to generate a high-voltage electric current. This current is then delivered to the plant through an arrangement of electrodes mounted either in front of, or behind, the tractor. This application destroys the plant's cell walls, resulting in either plant death or suppressing its growth.

More details about how electric weed control works are available in DPIRD’s October 2022 Protecting WA Crops newsletter.

In an experiment conducted this year as part of the electric weed control project, DPIRD research scientist Miranda Slaven examined the effectiveness of electroweeding in managing an annual ryegrass population that was tolerant to glyphosate, comparing it to conventional herbicide treatments. In the control plots where no treatment was applied, the average ryegrass density stood at 81 plants per square meter. With the application of glyphosate (Roundup Ultra Max at a rate of 1.5 L per hectare), this density decreased to 64 plants. Further, a 'double knock' treatment involving both the same application of glyphosate followed two weeks later by an application of paraquat with diquat (Sprayseed 250 at 1.5 L per hectare), led to a reduction in ryegrass density of 53 plants per square meter.

However, electric weed control was more effective than the herbicide treatments. These treatments reduced ryegrass density by more than half, with a single application resulting in 22 plants per square meter. Initial results from trials in 2022 indicated that the electric weed control machine was most effective at speeds of 1-2 km per hour for grass weeds and 2-4 km per hour for broadleaf weeds. This is attributed to the greater leaf surface area of broadleaf weeds, allowing for more effective plant-electrode contact. Interestingly, application speeds of both 2 and 4 km per hour were evaluated in this year’s trial with the herbicide tolerant ryegrass and were found to be equally effective at controlling the weed population in the single knock treatment applications.

These initial trial results indicate the potential of this new technology for use in problem areas of herbicide resistant weeds such as targeted applications in paddocks, along fence lines or roadsides, and for fire break maintenance. Additionally, there is the option to integrate this technology into existing on-farm weed management strategies as a proactive measure to mitigate the development of herbicide resistance in the future.

For more information on electric weed control refer to DPIRD’s October 2022 Protecting WA Crops newsletter, DPIRD’s Positive start to electric weed control trials media release or GRDC Research Updates paper ‘Investigating the application of electric weed control in Australian fallow scenarios’.