Sources of cloudiness or colouration of water

Dispersed clay is the usual cause of cloudy water. Sometimes, organic matter and materials precipitated from solution, such as hydrated iron oxides, may cause cloudiness. Dissolved or suspended material can colour water.

Changes to colour and quality of water are common after rain, when run-off containing soil and organic debris is collected in the dam or tank. These changes are particularly evident in water collected after a long dry spell.

Chemicals required

Certain chemicals can be used to coagulate the material in cloudy or discoloured water, into particles large enough to settle or filter, making them easier to remove. Alum (also known as filter alum, hydrated aluminium sulfate) is the most commonly used clearing agent for treating cloudy and coloured water. Other clearing agents, such as lime, gypsum, iron sulfate and calcium chloride, are suitable in some situations, but always check whether these will adversely affect the intended use.

Selecting a satisfactory treatment is a matter of practical testing.

Alum is acidic, and many low alkalinity waters (for example, fresh surface water) require a pretreatment with soda ash (sodium carbonate) or builders lime (hydrolime or calcium hydroxide). Test your water's pH to make sure. We recommend using soda ash rather than builders lime because it is safer to handle (see the Boral Cement hydrated lime safety data sheet), dissolves easily, and does not increase the hardness of the water.

You can buy filter alum and soda ash from swimming pool chemical suppliers, buy larger quantities from rural suppliers, and most hardware stores have builders lime.

If you choose to use builders lime, the quantity required is two-thirds of the soda ash requirement: for example, a recommendation for soda ash at 75 grams per cubic metre of water (1000 liters) is equivalent to 50 grams of builders lime per cubic metre of water.

To clear water

The 4 steps to clear water are:

- Get a laboratory analysis to decide the level of treatment.

- Select a suitable vessel for the water treatment.

- Add and mix the chemicals.

- Allow settling of the suspended material and remove the clear, colourless water.

Laboratory tests

We recommend getting a laboratory assessment of the water for any large-scale treatment with soda ash or builders lime. Small-scale tests at home may adequately assess the required dosage.

ChemCentre can provide you with more information and advice on phone +61 (0)8 9422 9800.

Treating water in tanks

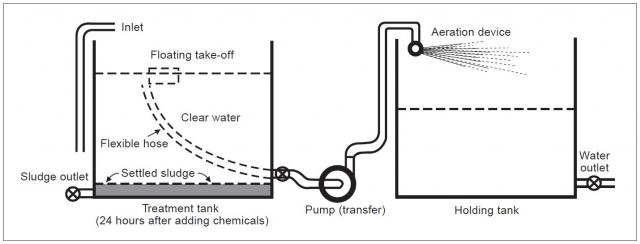

We recommend batch treatment of the water using 2 tanks – a treatment tank and a holding tank – as shown in Figure 1. Add the correct amount of chemicals (as recommended in the laboratory report) to the treatment tank. The holding tank requires no treatment other than aeration of the water before entry. The water inlet to the treatment tank should be above the maximum water level to provide moderate aeration.

The water inlet to the holding tank should be above the maximum water level. Aerate the treated water as it is transferred to the holding tank: use a pump or adequate head differences between the two tanks to form a fine spray that travels 1 to 2 metres before entering the main water body.

The treatment tank should have 2 outlets:

- one at the bottom so that the settled sludge can be flushed to waste

- one about 100–200 millimetres (mm) above the bottom for removing the treated water; alternatively, a floating take-off may be used.

The treated water in the first tank is generally corrosive and we recommend plastic, fibreglass or concrete tanks. Use a protective lining of cement or plastic if a galvanised tank is used. Other coatings are rarely completely effective and may give a disagreeable taste to the water. If using a fibreglass lining, allow sufficient time to cure.

The holding tank requires no protective coating because efficient aeration makes the water noncorrosive. The holding tank needs only 1 outlet, sited about 100 mm above the bottom.

Clarifiers

Continuous flow clarifier units incorporate chemical feed pumps that supply doses of soda ash and filter alum. The cost of these units is higher than the two-tank treatment method.

Treating water in dams

We recommend pumping from the dam and treating the water in tanks. Clearing or decolouring water in dams is not always satisfactory, because:

- wind action and water movement disperses the sludge formed by treatment

- inflow of untreated water counteracts the effect of earlier treatment.

Treatment can be improved by protecting the dam from wind, and diverting further inflow. Use a floating take-off, and pump and efficiently aerate the clear water into a holding tank.

The good news is that cloudy water from suspended clay is usually a sign that the water is very fresh.

Adding and mixing chemicals in a dam where a tank is not available

Calculate the amount of chemical required from the recommended laboratory dosage rates and the capacity of the treatment vessel.

Dissolve the chemicals into separate plastic buckets. Do not add soda ash and filter alum together in the same bucket because a reaction occurs which renders the clarification treatment useless. Mix builders lime into a uniform slurry before adding to the water.

Fill the treatment tank and then add the dissolved soda ash or builders lime slurry, and mix well. Add the dissolved filter alum separately and mix well. In a tank of less than 20 cubic metres (20 000 litres), use an oar as a stirrer to provide adequate mixing.

For treating water in dams, the plastic buckets can be replaced by small tanks, such as those used for firefighting. Spray the soda ash and filter alum solutions separately over the surface of the water, spraying less onto the shallow water at the edges of the dam.

After adding the soda ash, mix the water thoroughly, then add the filter alum and mix again. On larger dams, you can mix by driving a motor boat across the surface for an extended period or by dragging a branch of a tree or similar object repeatedly through the water.

Rinse the small tanks and pump immediately after use because the filter alum solution is corrosive. The treated dam water is also corrosive and the clear water should be efficiently aerated into a holding tank before use.

Settling suspended material and recovering clear water from a tank

Settling time

The time to settle may require 2 to 24 hours: allow treated water to settle overnight or for a full day before recovering the clear water.

Recovering clear water

The volume occupied by the settled material will vary – it is usually 2–10% of the original volume, but may be as high as 30% for exceptionally cloudy water.

We recommend using a floating take-off to remove the clear water (Figure 1). This take-off can be made to remain a certain distance above the bottom so that sludge is not picked up. A fixed outlet in the treatment tank as described earlier is also satisfactory.

As soon as the clear water has been removed, the sludge should be discharged to waste. Sludge left in the tank can prevent satisfactory treatment of the next fill.

Where the treatment tank has only 1 outlet and this is at the bottom, it is possible to flush the settled sludge to waste first, then collect the clear water through the same outlet. However, it is difficult to remove all the settled sludge and wasteful to use clear water for flushing.