In recent years, semi-leafless varieties with the sugar pod trait (for example, Kaspa and Moonlight) have been found to be well suited to swathing. The swaths are much more stable than conventional trailing types (for example, Dundale and Parafield) as the tendrils lock together and the sugar pod trait reduces pod shatter or pod loss. Semi-leafless lines that do not have the sugar pod trait, such as Excell and Snowpeak, are less suited to swathing, particularly at more mature stages, as they are more likely to shed seed.

In general, swathing conventional trailing peas (Dundale, Parafield etcetera) is not recommended as the swath is susceptible to being disturbed by the wind. Heavy swaths formed by windrowing conventional trailing peas with an expected yield of at least 1.5 tonnes per hectare (t/ha) are less likely to be disturbed by strong wind events.

Benefits of swathing:

- improves quality of harvested grain

- reduces soil contamination of grain due to reduced lodging, less earth tag (soil that sticks to pods and stems), with dirt or stones picked up often falling out of the swath

- reduces harvester maintenance costs

- rocks and roots often fall out of the swath, or if observed can be manually removed

- less earth tag reduces wear rates

- increases the time available for harvesting of field pea

- field pea can be swathed before they are ready to be direct harvested

- field pea can be swathed when all crops are too wet to direct harvest

- swaths can be picked up at any time – day or night

- swathing may reduce seed set of weeds.

Disadvantages of swathing:

- swathing is another operation and cost

- in wet conditions, both seed quality and yield may be at risk due to the swaths retaining moisture. In Canada, where the swathing of field pea and wet harvests are more common, growers resort to turning over damp field pea swaths in order to maintain seed quality

- crop-topping may be compromised because the timing of swathing and croptopping may not coincide.

Timing of swathing

When to start swathing

Snowball (1986) conducted a number of experiments on field pea swathing in the 1980s from which guidelines for the timing of swathing were established. Field pea can be successfully swathed from when 50% of the crop is still green or yellow and 50% of crop is brown.

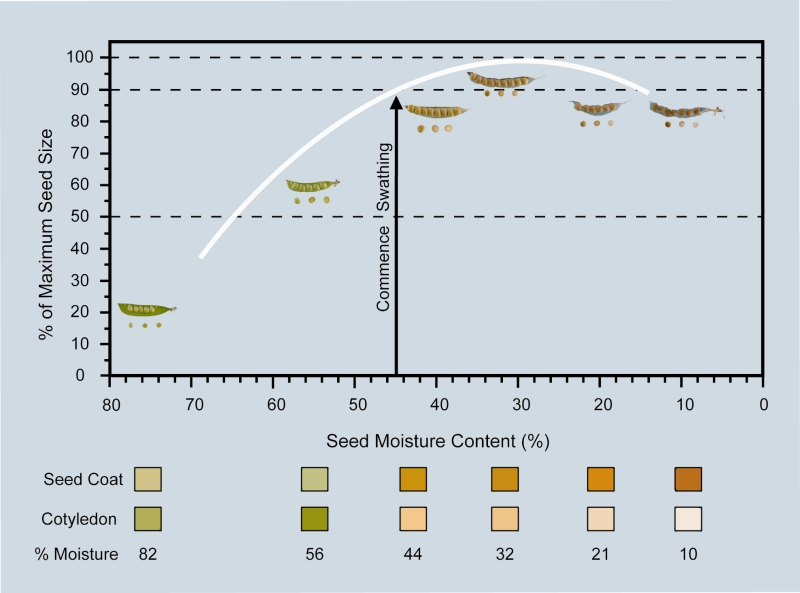

This often equates to an average seed moisture content (SMC) of 40-45%, with 60% of seed still large and moist and the remaining 40% of seed small and dry (SMC less than 25%) – see Figure 1 and Table 1.

| Seed size | Cotyledon colour of Kaspa | Seed moisture content (SMC %) | Comment |

|---|---|---|---|

| Large | Green  | Greater than 50 | Seeds in pods squash easily |

| Large | Yellow

| 40-50 | Time to start swathing |

| Large | Yellow

| 25-40 | Rapid drying |

| Small | Beige

| 12-25 | Seeds difficult to dent with thumbnail |

| Small | Pale pink

| Less than 12 | Seeds are hard |

If the crop is swathed too early, seeds will not fill properly and yield may be lost. Swathing too early may also increase the proportion of green cotyledons which can cause problems at delivery as milling peas cannot have more than 1% of poor coloured seed. If swathing is delayed until full maturity there is a greater risk of pod-shattering particularly in those varieties without the sugar pod trait.

The suggested time to commence swathing, 50% maturity (average SMC of 40-45%), is earlier than the 75% maturity (average SMC less than 30%) suggested for croptopping field pea. Growers must therefore assess the cost of a reduced field pea yield with the benefits of reducing weed seed set. To minimise yield loss, growers committed to reducing weed seed set by croptopping should use glyphosate, rather than diquat or paraquat. Alternatively, growers may choose to wait until the crop is at 75% maturity before croptopping and swathing. Swathing itself may reduce the seed set of weeds depending on the species of weed and the growth stage of the weed when it is swathed. In many instances, growers will need to use follow up non selective sprays over the paddock to stop regrowth or to minimise the seed set of weeds particularly if the heads of the weeds are below the swathing height.

When to stop swathing

Semi-leafless field pea varieties which possess the sugar pod trait such as Kaspa and Moonlight may be successfully swathed at later stages (75-100%) of maturity. Field pea varieties that do not possess the sugar pod trait may experience significant shattering if swathed at later stages of maturity. Growers have successfully swathed mature crops directly in front of the harvester under cool and damp conditions. If shattering becomes excessive whilst swathing, then cease operations and direct harvest the crop. Alternatively, stop swathing and return when conditions are cooler.

Machinery used for swathing semi-leafless field peas

Growers have swathed field pea with self-propelled swathers (for example, John Deere fitted with Honeybee swathing front, Case and John Deere fitted with MacDon swathing front, Case fitted with Case swathing front) and also used headers with offset or side release drapers (for example, New Holland fitted with Honeybee swathing front). All of which had either steel or plastic finger-tine reels.

If a batt reel is used, attaching rubber flaps is recommended to prevent bulldozing the crop at the cutter bar. Snowball (1986) used a tow-behind PTO swather and noted far wheel drag to be a problem which may be overcome by motorizing the far wheel, or joining the far end of the swather to the front of the tractor using rope, metal cable or chain with a spring section.

Crop lifters

Swathers are normally fitted with lifters at 30cm spacings. Lifters may have to be spaced closer (15cm) for short, thin crops. In thick, well-grown crops, growers have successfully swathed field pea without lifters which reduces the amount of soil brought onto the belts. However, on gravel soils, lifters may be necessary to allow small buckshot gravel to fall out of the crop as it is picked up.

Shorter lifters may be required if the crop is very short or the lifters may have to be removed to allow the cutter bar below the lowest pod. It is best to swath or direct head a lodged pea crop at right angles to the direction to which the crop is laying.

Adjustments to suit crop stage and bulk

Where possible, adjust the swather table to enable the cutter bar to be close to the ground and the crop to come off the draper evenly. Adjustment of the pick-up reel, backward or forward, may alleviate piling problems.

If swathing is delayed and the crop dries out, it is more likely to pile up on the knife and belts. It may therefore be necessary to alter the reel so the fingers are flatter and set to push the crop slightly downwards rather than lifting. A raised cross-auger fitted above the belt on the draper front may also assist in reducing piling in dry crops.

Be aware that when the crop is green the plant material often wraps around the raised cross-auger and it may be better to remove it.

It is important to match swath bulk and width to the capacity of the swather, rollers and subsequent harvester. In very well grown high yielding crops (greater than 2t/ha) the swath width may need to be narrowed so that the roller and harvester can deal with the large amount of material in the windrow. Similarly for offset discharge drapers, a full width cut may be too large and hinder the flow of material across the belt to the side exit.

In years when crops have grown well but, a dry spring limited yield, the flow of material out of the exit hole of drapers have created problems. In most other years a greater proportion of seed to tops will ensure a better flow of material. Some people have fitted a canvas shroud just behind the exit of a self-propelled swather, which improves the flow of material. The rollers used behind the exit hole of offset drapers may assist the flow of material.

Rolling of swaths

To minimise movement of the swath by the wind, field pea swathed at 50% maturity (that is, 50% of pods brown) must be rolled as soon as possible, ideally immediately after the swather. Wind tends to get under the start and end of runs, causing the swath to move. Keeping runs as long as possible will minimise wind damage.

Canola rollers work well on wind-rows of crops yielding up to 2t/ha. In very well grown crops with an anticipated yield above 2t/ha it may be necessary to make the roller wider by adding centre extensions. The shape of canola rollers may not be suitable for lighter field pea wind-rows with an expected yield less than 1.2t/ha because the edge diameter may be too large, and a flatter roller, like a tyre roller, may work better. Shedding has not been a problem when Kaspa swaths have been rolled with a rubber tyre roller.

On side-release swathers, some growers have fitted a fluted roller directly behind the exit hole enabling a one-pass swathing operation.

Harvest

Field pea can be safely harvested at 16% moisture and the grain will naturally dry out in an open stack or shed floor without any need for specialist aeration equipment prior to delivery. This allows a longer period over which wind-rows can be picked up because it can be done in cool and damp weather when most other crops cannot be harvested. It also enables the windrows at night to be picked up at night.

Varieties with the sugar-pod trait, however, may be harder to thresh and chop than other varieties in cool weather. In these cases conventional pick-up fronts can be used to harvest the swaths.

Seed crops

For grain to be retained as seed it is important to have good seed germination. Snowball (1986) showed the germination percentage of field pea was not adversely affected when the crop was swathed as high as 60% seed moisture content. Therefore seed can be kept from swathed crops provided growers swath no earlier than the suggested time (that is, 50% crop maturity and an average seed moisture content of 40-45%).

Seed crops should not be croptopped (desiccated) with glyphosate becauseit can reduce the germination and vigour of seed. Seed should be at 13% seed moisture content prior to storing in sealed silos.

All seed should be tested by a certified laboratory prior to planting. Consider buying new seed if the germination test is less than 80% because the seed may lack vigour or if the level of blackspot infection on seed exceeds 15%.

Acknowledgments

Funding provided by Grains Research and Development Corporation and the Department of Agriculture and Food, Western Australia. Illustration and editing by Pam Burgess. Photographs by Mark Seymour.

References

Snowball, R 1986, 'Harvesting methods in south coastal, high rainfall crops', Department of Agriculture Western Australia Division of Plant Research Technical Report, No.4, pp.112-120.