Irrigation Pumps

Irrigation pumps are used to create pressure and flow within an irrigation system. The maximum pressure and flow required is determined from an irrigation design, allowing the most suitable pump to be selected. Correct irrigation design and pump selection will provide good irrigation uniformity; with even application of both water and nutrients via the irrigation system.

There is a large selection of pumps with a wide range of specifications which is why irrigation designers will leave pump selection until last.

Before a pump is selected the following should be known:

- The volume and maximum abstraction rate of the water source supplying the system (this should be known before a design is done).

- The flow required by the irrigation system.

- The pressure required to operate the system (total dynamic head), including all losses caused by friction from pipes, fittings, valves, elevation and the pressure to operate the emitters.

- Whether the source of water will be above or below the pump.

- The source of energy to power the pumps motor.

The flow rate and pressure requirements of a pump, are known as the ‘pump duty’.

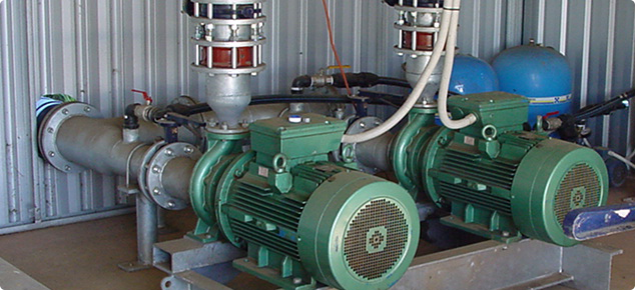

The three main types of pumps commonly used in irrigation systems in Western Australia are:

- Centrifugal pumps powered by electric or combustion (diesel) motors.

- Electric submersible pumps.

- Turbine pumps powered by electric or diesel motors.

Pump performance charts

A pump curve is a simple graph which shows the performance characteristics of a particular pump. Pump curves are created by the pump manufacturer and can generally be sourced from the manufactures website or the pump reseller.

A pump curve shows the pressure created by the pump at different flow rates. There is always an inverse relationship between pressure and flow. That is, as the pressure produced by the pump increases, the flow rate decreases and vice versa.

Depending on the emitter being operated, the pump required may need to deliver a large volume at low pressure (drip irrigation) or low volume at high pressure (overhead irrigation). Selecting the wrong pump may cost you money pumping pressure that is not required or lead to ineffective irrigation for the emitters selected.

Pump curves show the efficiency of the pump to convert energy to water flow and pressure. Selecting a pump that operates at its highest efficiency for the pressure and flow required will save on operating cost over the life of the pump.

Figure 1 is a simple pump curve for a 7.5 kilowatt motor. It has three impeller diameters all suitable for the pump. Pump flow (metric) is shown on the lower horizontal axis (L/sec, m3/hr), while pressure in metres is shown on the left hand vertical axis. One metre of pressure is approximately 10 kPa.

To determine the pressure at a given flow, draw a vertical line from desired flow rate on the flowrate axis to the curve that matches the size of the impeller you are considering. Then, from the point on the curve, draw a horizontal line across to the pressure axis. Where the line intersects the vertical axis will be the pressure delivered at the particular flow selected. For this example, 27.5L/sec (99m3/hr) will be delivered at 18m pressure.

To work out the flow at a given pressure, draw the line horizontally from the desired pressure to the curve and then vertically to determine the flow delivered at a given pressure.

To find the pump efficiency, look at the percentage numbers on the curves. Where the flow and pressure (pump duty) intercept the curve for the impeller being used, the point will fall between two efficiency lines. In this case the lines meet between the 73% efficiency points, the highest efficiency for this pump.

Selection of the wrong pump can lead to pump damage and costly repairs. When the suction of a pump exceeds the force holding a water molecule together, rapid occurrence and collapse of vapour bubbles occurs. This is called cavitation. The vapour bubbles can explode with enough force to pit or tear metal surfaces, damaging the internals of a pump. This will often happen with centrifugal pumps that are lifting water beyond what is call the maximum allowable lift. As both water temperature and altitude increase, the maximum allowable lift will decrease.

Key Points

- Pump selection should be based on the ‘pump duty’, i.e. flow and pressure required.

- Pump duty should be calculated to match the peak flow of each watering shift of an irrigation system.

- An irrigation designer is best qualified to design an irrigation system. For a list of certified irrigation designers follow this link to Irrigation Australia’s link of certified irrigation designers.

- A pump specialist and irrigation designer should both have the expertise to assist with selection of an appropriate pump. Pump manufacturer websites will often contain details of specialist dealers who can assist with pump section.

Rohan Prince, DAFWA and Neil Marriott, Challenger Institute of Technology